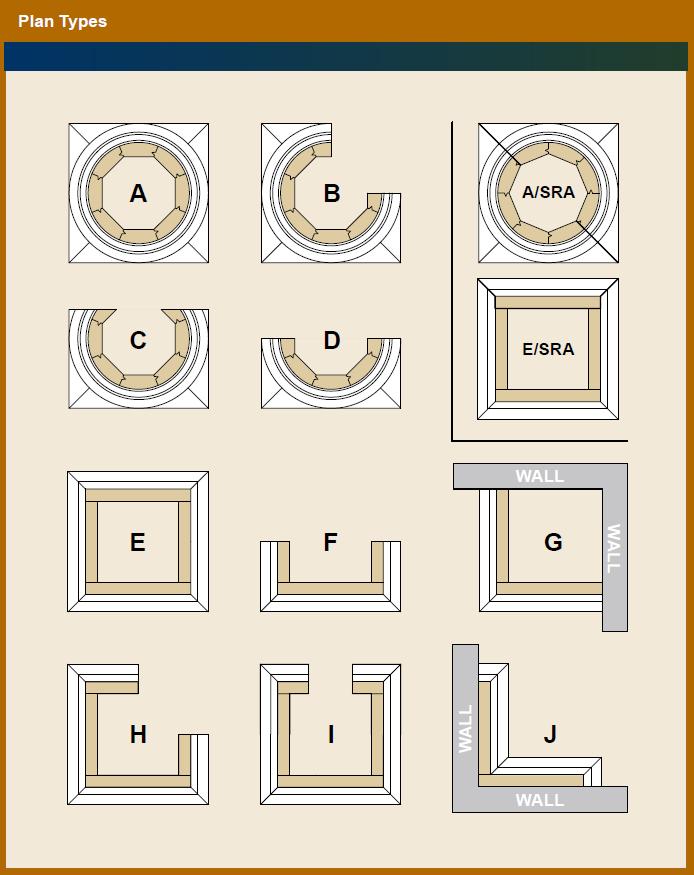

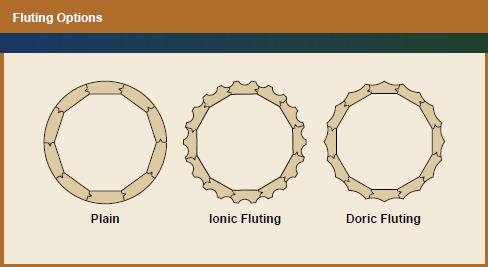

Provide style number and plan shape. Indicate whether for interior or exterior use, quantity. and species of lumber. Supply information called for in specifications and details, diameter at top and bottom, overall length, primed or unprimed, type of flashing if to be supplied by Somerset. Indicate if column is to be made split for re-assembly to fit around existing structural member and include inside opening dimension. Furnish the same information for pilasters and square columns and also provide dimensions of returns. Pilasters can be manufactured in any style to match columns, either tapered or straight with the same width as either the top or bottom diameter of matching columns.

Provide style number and plan shape. Indicate whether for interior or exterior use, quantity. and species of lumber. Supply information called for in specifications and details, diameter at top and bottom, overall length, primed or unprimed, type of flashing if to be supplied by Somerset. Indicate if column is to be made split for re-assembly to fit around existing structural member and include inside opening dimension. Furnish the same information for pilasters and square columns and also provide dimensions of returns. Pilasters can be manufactured in any style to match columns, either tapered or straight with the same width as either the top or bottom diameter of matching columns.

Installation

All columns before leaving the factory are crated or protected in such manner to prevent damage. When they arrive on the job site they should be stored in a dry place. and immediately upon installation several coats of paint should be applied. Ventilation must be provided top and bottom in accordance with Somerset’s Installation Procedures on exterior columns.

Specifications

1.0 General

1.1 Description:

A. Columns shall be manufactured by Somerset Door and Column Company- according to their Design No. (Use design number in catalog or if the design is to be made to architect’s detail state. “To be made according to architect’s detail.”)

B. Column design shall have the correct proportions based on Orders of Architecture.

C. Lumber species shall be (African Mahogany) (Cherry) (Clear Northern White Pine) (Maple) (Northeastern Knotty White Pine) (Oak) (Poplar) (other).

1.2 Submittals

A. Submit Somerset product data and details clearly marked to show column requirements.

1.3 Delivery, Storage and Handling

A. The protection. delivery, storage, and handling of the columns and pilasters shall be according to the instruction furnished by the manufacturer. Storage must be in a dry and well-ventilated area

B. Immediately upon installation, several coats of paint must be applied to insure weatherproofing.

2.0 Products

2.1 Acceptable Manufacturers:

A. Somerset Door and Column Company

174 Sagamore Street

Somerset, Pennsylvania 15501

800-242-7916

2.2 Materials

A. All tongue and groove glue joints shall be pressure-glued using appropriate glue.

B. Columns which are to be painted shall be factory coated with two applications of appropriate primer and hand sanded between coats as

necessary. All columns designated for exterior application are to be coated inside with a black asphalt compound for waterproofing.

C. Plinths shall be (Specify fiberglass or aluminum for exterior and wood for interior) and shall be manufacturer’s standard proportions for diameter indicated. (If special size or shape is required indicate here or refer to appropriate detail.) For stone or similar plinth. aluminum ventilating plates are to be furnished for installation between wood and stone.

D. Wood and composition caps shall be flashed with (stainless steel) or (16 oz. copper) provided by column manufacturer.

E. Composition capitals shall be made of fiber reinforced number one casting industrial grade plaster or resin polyester using manufacturer’s standard mold of the design indicated.

F. All matching pilasters or square columns shall be made by the column manufacturer consistent with the above specifications.

3.0 Execution

3.1 Installation

A. Follow manufacturer’s detailed installation procedures.

4.0 Take-Off

A. Somerset Door & Column Company is not responsible for anything missed on Take-offs.

B. Customer shall review Somerset Door & Column Company quotes to verify all items and quantities are in accordance to customer Take-offs.